Tungsten and Molybdenum Capabilities

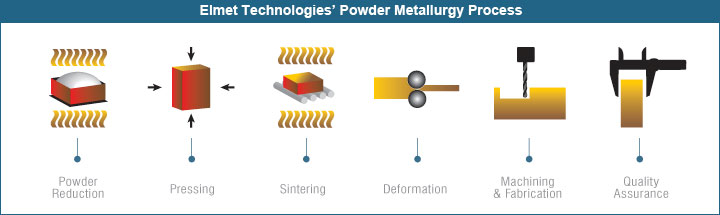

When Tungsten and Molybdenum material characteristics and properties must be critically controlled for superior end product performance, customers rely on Elmet Technologies’ unmatched expertise in the field of powder metallurgy. Our advanced powder processes to produce pure Tungsten and Molybdenum metal powders as well as specific metal alloys. By selectively influencing aspects of the metallurgical process, we can change characteristics like porosity, strength, and temperature resistance to meet our customers’ specific needs.

At Elmet, our process is fully integrated and starts with the raw material, metal oxide, which is then purified to Tungsten and Molybdenum metal powder through a chemical reduction process. The powder is formed into semi-finished products through a series of advanced mixing, pressing, deformation and heating technologies. Finished products are then carefully manufactured to customer specifications utilizing our state-of-the-art machining and fabrication techniques.

Deformation Processes

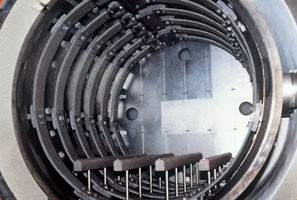

Elmet utilizes a variety of tungsten and molybdenum metal deformation processes to meet the unique needs of each customer application. Our processes have been developed over decades of working with tungsten and molybdenum and our experts continuously improve methods and controls to ensure our processes yield the material properties required for the existing and emerging applications. Elmet’s fully integrated manufacturing facility offers a complete range of deformation capabilities allowing application-specific conversion of metal powder to end product:

- Tungsten and Molybdenum Rolling

- Tungsten and Molybdenum Swaging

- Tungsten and Molybdenum Drawing

- Tungsten and Molybdenum Spinning

Engineering

With years of experience manufacturing solutions for the most demanding tungsten and molybdenum applications, our highly qualified team at Elmet Technologies provides you with the knowledge and expertise required for your success. Providing integrated engineering and manufacturing solutions associated with molybdenum, tungsten, and other refractory metals, we excel by exceeding the needs of our customers. Our engineering and operations teams will partner with our customers to advise options and solutions to the most challenging requirements. Customers benefit from gaining direct access to our experts – rather than working through numerous layers – for the invaluable information that will aid in solving their challenges. The accessibility to this expertise is unprecedented in the field and is a key component to Elmet’s proven track record of high customer satisfaction. Elmet can offer improved “total cost of ownership” solutions to our customers by leveraging our metal production expertise, precision machining capabilities, and fabrication services in our ISO 9001 and AS9100 certified factories.

- Material Expertise: providing consultation and advice on material selection and properties

- Product design advice (final designs are customer responsibility)

- Manufacturing Expertise: providing consultation and recommendations

- Manufacturing and development

- 2D and 3D Engineering drawing production (product drawings, assembly drawings)

- Failure Analysis

Near Net Shaping

Traditional Tungsten and Molybdenum finishing techniques such as machining and grinding can significantly add to production costs. Near Net Shaping produces an initial production shape that is very close to the final product shape, minimizing machining time and saving money. Elmet can provide design input and advice for custom pressed and sintered Tungsten and Molybdenum products to meet your specifications. Our 75+ years of Tungsten and Molybdenum experience enables us to produce a wide variety of geometries from crucibles to shape charges and more to enable cost-effective manufacturing and finishing of your products.

Material Analysis

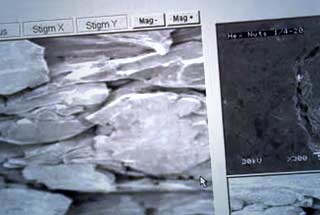

A thorough understanding of materials is pivotal to the success of any process. Today’s advanced technologies requiring characteristics such as high-temperature operation, excellent corrosion resistance and low thermal expansion place high demands on material performance. At Elmet Technologies’ Tungsten and Molybdenum material analysis laboratory, we provide an array of expert analytical services required for materials research and process troubleshooting. Our laboratory is equipped with state-of-the-art equipment to ensure accurate and precise measurements and analysis. Elmet leverages relationships with world-renowned experts from top U.S. research institutions in order to provide our customers with the most advanced analytical capabilities.

Analysis:

- Atomic absorption spectroscopy

- Optical emission spectroscopy

- Powder Analysis

- SEM with EDX

- Metallography

Testing:

- Mechanical Testing & Characterization

- Non-Destructive Testing

Refractory Metal Machining

At Elmet Technologies, we pride ourselves in offering our customers sophisticated tungsten and molybdenum machining and fabrication capabilities that have been honed over decades of experience with two of the most challenging materials to machine: molybdenum and tungsten. We operate more than 70 machines dedicated to supporting your precision machining and fabrication requirements. Below is a brief list of some of our current capabilities. Please contact Elmet with your requirements for machining and fabrication. Material expertise includes:

Materials

- Molybdenum (Mo) Machining

- TZM Machining

- Mo-La Machining

- Mo-Ti Machining

- Tungsten (W) Machining

- Tungsten Heavy Alloy Machining

- Tantalum Alloy Machining

- Lanthanum Alloy Machining

- Contact us for other difficult-to-machine refractory materials

Machining Capabilities

- CNC VMC (3-axis), HMC (4-axis), Lathe (3-axis), and Bed Mill Machines

- Grinding, Lapping, and Polishing

- Threading

- EDM, Laser, 5-axis Water Jet Cutting

- Gun drilling

- Spinning

- And much more

Fabrication & Assembly Capabilities

- Welding, soldering, brazing

- Riveting

- Metal Forming, Folding and bending

- Punching and stamping

- Complex assembly

Advanced Automated Manufacturing

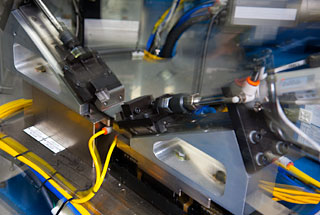

Elmet Technologies has extensive experience engineering and constructing automated manufacturing systems for the most challenging refractory metal assemblies. Our expertise enables our customers to realize designs once thought too costly or complex, and to accelerate the integration of new technologies into their products.

- Engineering: Elmet engineers and constructs the manufacturing line to optimize your production requirements. We employ advanced technology to automate assembly, including mechanical shaping, thermal treating, bonding, and robotics.

- Tolerances: Our production capabilities allow us to assemble the most complex customer designs to extremely tight tolerances.

- Scale: We can scale the specific automated manufacturing line with solutions needed to precisely and competitively build your product.

Vision Control Systems

Elmet is a pioneer in vision control monitoring systems in the manufacturing of refractory metals. These advanced systems ensure even the highest levels of quality are met.

- Construction: Our current systems are engineered to measure tolerances down to 20 micrometers and can process thousands of measurements in seconds in a closed-loop system for real-time production adjustments. The system captures, stores, and analyzes data that is used in creating customized reports.

- Quality: Elmet is capable of achieving 6-sigma level quality in automated lines that incorporate vision control systems.

Logistics

Your profitability – and your reputation – requires availability and prompt delivery of critical Tungsten and Molybdenum components. When process-critical equipment goes down and repair parts are required, you can depend on the responsive team from Elmet Technologies to get you or your customers back online – quickly. Elmet provides customers with same-day or next-day shipment service for common stocked sizes of our molybdenum and tungsten mill products. From semi-finished to standard mill products, Elmet’s well-stocked warehouse keeps critical equipment up and running. Common stocked molybdenum and tungsten products include:

- Tungsten and Molybdenum Rod – ground, clean finish

- Tungsten and Molybdenum Threaded Rod

- Tungsten and Molybdenum Sheet

- Tungsten and Molybdenum Plate

- Tungsten and Molybdenum Wire

- Tungsten and Molybdenum Hex nuts

Elmet Technologies Warehouse Stocking List 2019

Elmet Technologies accepts Visa® and MasterCard® for purchases made from our Service Center on a freight collect or prepaid basis.