Industries we support

Elmet Technologies provides tungsten and molybdenum engineered solutions for the most demanding industry applications. We understand that our success is about your success and that great products come from great relationships.

At Elmet, we are committed to solving our customers’ toughest refractory metal challenges by providing a superior portfolio of products, leading technical expertise and unmatched personalized service. Elmet Technologies’ proven experience in advanced material products stimulates development, improves performance and reduces costs.

We serve a wide range of industries that have come to rely on our superior products and services:

- Sapphire Crystal Growth

- High-Temperature Furnace

- Flat Panel Display

- Aerospace

- Medical Imaging & Devices

- Thin Film Coating

- Defense

- Energy

- LED

- Lighting

- Electronics – heat sinks, disks, and studs

- Semiconductor Process Tooling

Aerospace

The aerospace industry relies on high-temperature applications for aircraft turbines, outer skin structures, and rocket propulsion systems. Moreover, components with excellent corrosion and abrasion resistance are required to withstand the hostile environments experienced by high-performance air transport.

Elmet Technologies provides advanced tungsten and Molybdenum solutions to the aerospace industry’s most rigorous requirements by offering a wide array of high-quality components:

- Precision Machined Components

- Ballasts

- Performance Skins

Thin Film Coating

Elmet provides advanced tungsten and molybdenum solutions for semiconductor, solar, LED and display coating applications. Whether in sputtering, evaporative deposition or in epitaxy, the efficiency of the coating process and the performance of the film is highly dependent on the quality and purity of the source material. Elmet Technologies ensures superior coating results by providing the most advanced materials solutions. We will work closely with you to understand the requirements of your coating needs and then tailor our products to optimize the coating’s performance.

- Sputtering Targets and Materials

- Tungsten and Molybdenum planar and rotary sputtering materials and targets

- Evaporative Deposition Crucibles and Boats

- Electron beam and resistive evaporative deposition crucibles and boats

Defense

Elmet Technologies supports the military and defense industries’ mission-critical applications by providing Tungsten and Molybdenum products of unmatched quality and reliability. Because these high stakes applications are of extreme importance in areas such as national security, Elmet follows strict quality control procedures; all products meet the most stringent specifications. Military and defense contractors rely on Elmet’s expertise in manufacturing products requiring the unique material properties of molybdenum, tungsten and their respective alloys. Elmet’s defense product include:

- Kinetic energy penetrators

- Near net shape preforms

- Fragmentation sleeves

- Molybdenum and tungsten metal powders

- High-performance diode studs

- X-ray shielding

- Wire, sheet, and components for microwave tubes

Sapphire and Diamond Growth

Elmet produces molybdenum and tungsten material and components for leading sapphire growth furnace OEMs and crystal growers around the world. Elmet provides a variety of crucibles for sapphire growth furnaces, as well as many other components for these furnaces. Corrosion resistance, creep resistance, and high-temperature performance make molybdenum and tungsten crucibles ideal for use in high-temperature crystal growth processes. Crystal growth is at the foundation for many cutting edge technologies such as Sapphire touch screens, LED lighting parts, solar cells, and high power lasers. Elmet is continually improving manufacturing and materials processes to meet the evolving requirements of this industry. From raw material to finished product, Elmet’s integrated manufacturing process, quality systems, and metallurgical expertise ensure we deliver quality components for the crystal growth industry.

Powder is pressed and sintered to final shape geometries to meet the requirements of each customer’s furnace design.

Spin-Formed Molybdenum Crucibles

Large molybdenum plate blanks are hot spun-formed to the specified product geometry

Elmet has experience in a wide variety of molybdenum crucible sizes up to 20″ diameter

Milled Tungsten Crucibles

Material blanks are machined to the final product geometries

Display

Elmet Technologies’ high-quality Tungsten and Molybdenum sputtering targets and consumables aid the FPD industry in increasing throughput, improving uniformity and enhancing product performance. Elmet’s fully integrated Tungsten and Molybdenum production process allows complete control of the material purity to ensure customers receive the highest quality sputtering materials. As a leading supplier of planar and rotary sputtering targets, Elmet works closely with customers to ensure all specifications are met – from the initial metallurgy to the final end product. Adhering to high-quality standards, Elmet’s manufacturing consistency enables customers to achieve stable fabrication processing and superior product performance.

- Tungsten and Molybdenum Planar and rotary sputtering materials and targets

Energy

Expertise in high-performance Tungsten and Molybdenum materials has highlighted Elmet Technologies as a leading supplier in advanced energy-related applications. From molybdenum sintering boats found in the nuclear fuel processing industry – to refractory metal components associated with fuel cells – Elmet thrives on meeting the needs of these evolving energy technologies.

Solar/ Thin Film Photovoltaics

Bolstering global renewable energy sources, the photovoltaic industry uses solar cells to generate electricity by harnessing the power of the sun. Leading thin film photovoltaic technologies consist of multiple layers of deposited thin films including molybdenum – commonly used as the back metal contact. The characteristics of this thin, sputtered layer contribute significantly to overall cell performance, efficiency, and reliability. Manufacturers rely on high purity molybdenum planar and rotary sputtering targets provided by Elmet Technologies to increase performance and improve yields as they progress towards grid parity.

In addition to the targets themselves, Elmet supplies molybdenum and tungsten components for the thin film deposition systems required in downstream processing of solar cells. Touting exceptional thermal and physical stability, refractory metal components manufactured by Elmet ensure coating systems achieve maximum up-times, yields, and throughputs.

- Solar / Thin Film Photovoltaics

- Tungsten and Molybdenum Planar and rotary sputtering targets in addition to precision machined components used in processing equipment

Nuclear

Sintering is a critical step in nuclear fuel production. Elmet is a recognized leader in manufacturing Tungsten and Molybdenum sintering boats and carriers for production of nuclear fuel.

Nuclear Fuel Processing

Tungsten and Molybdenum Sintering boats and other components used the fuel processing furnacesFuel Cells

Customer specified Tungsten and Molybdenum components used in the high-temperature solid oxide fuel cells

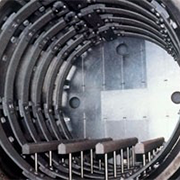

High-Temperature Furnace

The high melting points characterized by the material properties of molybdenum and tungsten make these metals the ideal choice for vacuum and high-temperature furnaces. Elmet Technologies is a leading supplier in furnace components, including shielding, racks, fixtures, crucibles, sleds and mill products such as threaded rod and sheet required for assemblies and rebuilds. For your immediate needs, standard molybdenum and tungsten mill products are in stock and ready for delivery; special customer designs are manufactured.

- Sintering Furnace

- Vacuum Furnace

- Walking Beam Furnace

- Continuous Furnace

- Hot Isostatic Pressing (HIP)

- Crystal Growth

LED

Advanced Molybdenum and Tungsten components for use in LED manufacturing processes.

Light emitting diodes (LEDs) have many advantages over incandescent lighting, including lower energy consumption, smaller size, longer lifetime, faster-switching ability and better reliability. The low energy consumption, compact size, and fast switching capabilities make LEDs ideal for use in backlighting and general lighting applications.

Most high brightness LED chips are fabricated using an epitaxial process whereby layers of semiconductor materials are deposited onto a sapphire substrate inside an MOCVD reactor. Elmet Technologies supplies the entire LED ecosystem with the highest quality molybdenum and tungsten components and assemblies ensuring thermally stable and contamination-free processing.

MOCVD Reactors

Elmet provides molybdenum and tungsten components and assemblies to the MOCVD industry. As the industry continues to evolve, Elmet works with our customers to develop the next generation products to will further increase yield and reduce cycle time.

Thermal Management

Since over 90% of the heat generated by an LED is dissipated out of the back of the device, thermal management solutions are critical to maintaining the expected performance of the device.

Elmet supports high power LED applications by providing molybdenum heat sink designs that effectively conduct heat to maintain the integrity of the device.

Lighting

Elmet Technologies has a long history of offering a broad spectrum of both general and specialty lighting Molybdenum and Tungsten components. In fact, Elmet began supplying Tungsten filaments and coils to the lighting industry in 1929. While expanding into new markets, Elmet continues to be a leading supplier of high-quality Molybdenum and Tungsten components including coils & filaments, specialty leads, and more. Elmet’s products enable peak efficiency from a wide array of traditional lighting sources as well as from new, high efficiency and environmentally friendly sources.

Incandescent lamps

Filaments, coilsHalogen lamps

Filaments, coilsFluorescent lamps

Electrodes, cathodesCCFLs (Cold Cathode Fluorescent Lamps)

Electrodes, cathodesSolid State Lighting / LED (Light Emitting Diodes)

Products used throughout the fabrication process from sapphire growth, thin film deposition, thermal managementMedical Devices

The unique material properties of tungsten and molybdenum play valuable roles in today’s state-of-the-art medical equipment. Elmet Technologies is an experienced provider of high-performance molybdenum and tungsten components found in medical imaging systems such as X-ray tube components and collimators. In addition, Elmet supplies precision machined and fabricated products for medical device applications.

Medical Imaging

Quality imaging techniques also play an invaluable role in medical diagnostics by improving image quality, reducing exposure, and limiting costs. Advanced X-ray and radiotherapy applications require materials that are capable of withstanding thermal stress resulting from extreme temperatures. Moreover, materials impervious to X-rays and gamma rays are critical in shielding and detector applications.

Elmet Technologies works closely with OEMs to develop products for their systems. Elmet has already set the standard for the CT imaging detection systems. We continue to contribute to the success of medical imaging by manufacturing the highest quality molybdenum and tungsten components for X-ray tubes, collimators, and shielding used in diagnostic and therapeutic systems.

Medical Imaging

Molybdenum and Tungsten Collimators, X-ray tube components and other critical performance components used in imaging systemsMedical Devices

Molybdenum and Tungsten Precision machined products and fabrications per customer specificationsNuclear Medicine

Molybdenum and Tungsten Shielding and collimators for diagnostic and therapeutic applicationsSemiconductor Process Tooling

Engineered molybdenum and tungsten components for global semiconductor process tool OEM’s. Hundreds of processing steps are required in the manufacture of semiconductors; many of which occur within reactors that are exposed to harsh thermal and chemical conditions. The performance characteristics of equipment components are critical. The high melting point and superior corrosion resistance of molybdenum and tungsten enable these materials to withstand extreme tool environments. For over 20 years, Elmet has supplied high-quality components for a variety of semiconductor tools.

- Ion Implantation

- Elmet precision machines and forms components, filaments and assemblies from Tungsten, Molybdenum, TZM, Tantalum and other metals used in Ion Implant equipment.

Electronics

Elmet Technologies provides high quality, precision machined molybdenum and tungsten components for processing equipment used in the manufacture of semiconductors, including Ion Implantation, MOCVD, CVD, PVD, and MBE tools. Supporting an industry reliant upon high purity molybdenum and tungsten materials, high service levels, and global needs, Elmet’s strength in innovation allows its customers to remain competitive in the global marketplace. Adding to the specific needs of the Process Tooling Industry, Elmet molybdenum and tungsten provides products to the broader semiconductor and electronics market. Elmet’s product solutions support power semiconductors, crystal growth, and thermal management technologies.

Process Tooling

Providing molybdenum and tungsten precision machined components for OEMs and the aftermarket for tooling including ion implantation, MOCVD, PVD, and MBEProcess Materials

Molybdenum and tungsten planar and rotary sputtering materials and targets

- Ion Implantation

Power Semiconductors

Molybdenum components for high power diodes and thyristorsThermal Management

Providing tungsten and molybdenum heat sinks and heat spreaders for high power applicationsCrystal Growth

Molybdenum and tungsten furnace components including hot zones, crucibles, and other components used in single crystal growth furnacesLED

Products used throughout the fabrication process from sapphire growth, thin film deposition, to thermal management