Key Segments and Products

Elmet ensures the quality and performance of our molybdenum, tungsten, TZM, MoLa, and WHA products by starting with only the highest quality powders. Elmet is fully integrated, so we can tailor the manufacturing process to meet specific refractory metal and application requirements.

Performance Metals for Defense, Aerospace and Munitions

Defense Product Areas

- Swaged tungsten rod for kinetic energy penetrators

- Near net shape preforms

- Fragmentation sleeves

- Molybdenum and tungsten metal powders

- High-performance diode studs

- X-ray shielding

- Wire, sheet, and components for microwave tubes

- High ductility molybdenum plate

- Fragmentation balls/shapes

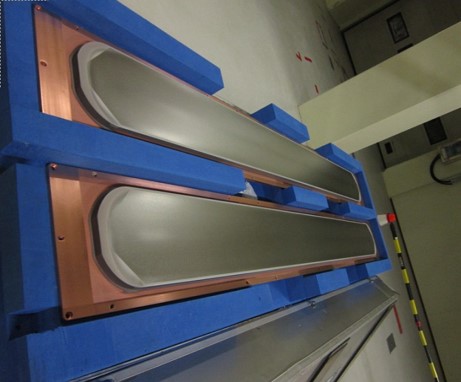

SPUTTERING TARGETS:

Elmet Technologies’ high-quality tungsten, molybdenum, and alloy based sputtering targets and consumables aid the FPD industry in increasing throughput, improving uniformity and enhancing product performance.

SPUTTERING TARGETS AND MATERIALS

- Tungsten and molybdenum planar and rotary sputtering materials and targets

- Broad capability of sizes covering Gen 1 to Gen 8.5

- Strip, Square and Monolithic

- Over $30 million in recent capital investments to support our target production capabilities

- Pure molybdenum (Mo), molybdenum-tantalum alloy (MoTa), tungsten (W), and molybdenum titanium (MoTi)

- Global bonding capabilities and a track record of delivering to leading display companies in US, EU, Taiwan, Japan etc.

- We also offer electron beam and resistive evaporative deposition crucibles and boats

REFRACTORY METAL Fabrications and precision MACHINING

As technologies advance, component and assembly specifications become more stringent. Consequently, machining and fabrication techniques must support demanding precision requirements and increasingly complex geometries.

At Elmet, we pride ourselves in offering our customers sophisticated tungsten and molybdenum machining and fabrication capabilities. We’ve honed our process over decades of experience working with molybdenum and tungsten, two of the most challenging materials to machine. Elmet operates more than 70 machines at our US plants that are dedicated to supporting your precision machining and fabrication requirements. See below for a brief list of some of our current capabilities.

REFRACTORY METAL MACHINING

- Molybdenum (Mo) Machining

- TZM Machining

- Mo-La Machining

- Mo-Ti Machining

- Tungsten (W) Machining

- Tungsten Heavy Alloy Machining

- Tantalum Alloy Machining

- Lanthanum Alloy Machining

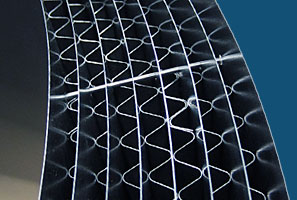

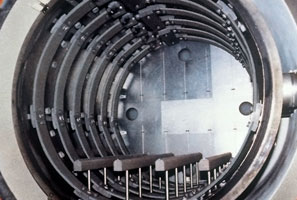

HOT ZONES & Furnace Parts

Elmet is also a leading global supplier of molybdenum and tungsten products to the high-temperature furnace industry. The hot zone designs at the heart of these furnaces can range from basic to complex and involve any number of parts from mesh elements to shielding to precision machined components. We support our customers’ hot zone needs with off-the-shelf stock, custom machined components, and by fabricating complete assemblies to customer specifications. In addition, we leverage our expertise to partner with our customers to advise improvements to their hot zone designs.

HIGH-TEMPERATURE Furnace Applications:

- Sintering Furnace

- Vacuum Furnace

- Walking Beam Furnace

- Continuous Furnace

- Hot Isostatic Pressing (HIP)

- Crystal Growth

MOLYBDENUM STUDS & HEATSINKS

Elmet is the leading global provider of pure molybdenum studs for power semi devices, high power diodes, and thyristors.

Elmet offers numerous sizes and options of molybdenum studs, disks and heat sink components. Please contact us to discuss your application.