Molybdenum SPUTTERING TARGETS:

Elmet is a global leader in production of Gen 1 to Gen 8.5 sputtering targets for the flat panel display industry. Our advanced tungsten and molybdenum solutions also support Semiconductor, Solar, LED and other Display thin film coating applications. Whether in sputtering targets, evaporative deposition or in MOCVD / epitaxy, the efficiency of the coating process and the performance of the thin film is highly dependent on the quality and purity of the source material. Elmet Technologies ensures superior thin film coating results by providing the most advanced materials solutions. We work closely with our customers to understand the requirements of their thin film coating needs and tailor our products to optimize the performance on their coating. Elmet Technologies’ high-quality tungsten, molybdenum, and alloy based sputtering targets and consumables aid the FPD and IC industry in increasing throughput, improving uniformity and enhancing product performance. Elmet’s fully integrated tungsten and molybdenum production process allows complete control of the material purity and microstructure to ensure customers receive the highest quality sputtering materials. As a leading supplier of planar and rotary sputtering targets, Elmet works closely with customers to ensure all specifications are met – from the initial metallurgy to the final end product. Adhering to high-quality standards, Elmet’s manufacturing consistency enables customers to achieve stable fabrication processing and superior product performance.

Sputtering Targets and Materials

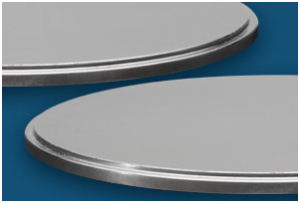

- Tungsten and molybdenum planar and rotary sputtering targets and materials

- Broadest capabilities of sizes covering Gen 1 to Gen 8.5

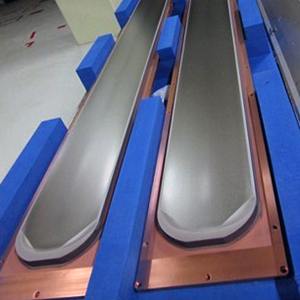

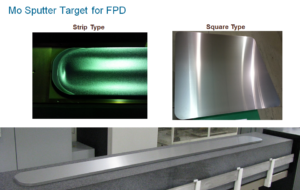

- Strip, segmented, square and monolithic (bonded and unbonded)

- Over $30 million in recent capital investments to support our target production capabilities

- Targets made of pure molybdenum (Mo), molybdenum tantalum alloy (MoTa), tungsten (W) and other alloys available

- Global bonding capabilities and a track record of delivering to leading display companies in the US, EU, Taiwan, Japan etc.

- We also offer electron beam and resistive evaporative deposition crucibles and boats

Innovation

As requirements in industries have changed, Elmet has continually innovated to meet industry needs and our customers’ requirements. Our team partners with our customers to fully understand the application requirements of current and future generations. Whether it is changing in generational geometry, material composition, or density, Elmet has the technical and manufacturing capabilities to understand and meet your specific needs.

Unmatched Material Quality

Our sputtering target material offers exceptional performance resulting from our powder metallurgy and manufacturing expertise. Elmet is a recognized global leader in delivering the highest quality, most reliable molybdenum and tungsten material for sputtering applications. These applications demand high levels of homogeneity, density, and purity – attributes that we deliver target after target for our customers.

| Generation | Dimension Examples(mm) |

| G8.5 Molybdenum Sputtering Target | 2650*210*18 |

| G7 Molybdenum Sputtering Target | 2650*200*16 |

| G6 Molybdenum Sputtering Target | 2350*200*16 / 2300*1800*14 |

| G5.5/5 Molybdenum Sputtering Target | 1950*1580*14/1700*1431*14 |

| G4 Molybdenum Sputtering Target | 1200*1130*10 |

| G3 Molybdenum Sputtering Target | 950*860*16 |

Note: Elmet can also provide the molybdenum rotating target for the whole generation line.

Elmet Technologies is dedicated to serving the FPD industry worldwide.

- World class quality and consistency

- A broad range of capabilities to enhance our customers’ competitiveness

- Price competitiveness vs. all global suppliers

- More than 10 years of experience in the FPD industry

- A proven history of vertically integrated material manufacturing and supply

- Global bonding capabilities close to customers

- Strong, dedicated local engineering and technical support

- Strong, dedicated local logistical supports

- A dedicated stocking program to ensure on-time delivery

- Over $30 million in recent capital investments to support our target production capabilities