Molybdenum Plate Products

Elmet is a global leader and the only US owned and operated manufacturer of molybdenum plate. Elmet offers high quality 99.95% pure molybdenum plate in standard plate thicknesses and with over $30 Million in recent capital investments we now also provide extra wide plate (>24″) and with increased thickness capabilities (up to 2″). We can cut, size, or roll the products to customer-specified thickness, length, and surface finish, as well as customize other material properties.

Elmet manufactures and stocks numerous sizes of molybdenum plate. Molybdenum plate is used in a diverse array of applications including precision sputtering targets, machining blanks, furnace hearth rails, x-ray shielding, nuclear fuel sintering boats, and others.

Product Description:

- Elmet can provide either stress-relieved or recrystallized product depending on customers’ use and application for material

- Made in the USA at our fully integrated Lewiston, Maine facility

- Designed to exceed ASTM specifications

- ISO 9001 and AS9100 certified manufacturing process

- Various finishes and sizes available upon special order

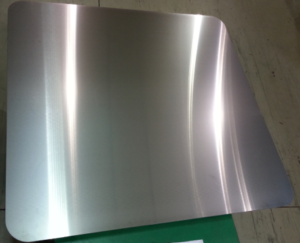

Molybdenum Sheet Surface Condition

Surface can be supplied in a shiny, matte, satin, or as-rolled condition; dependent upon thickness and width parameters.

Molybdenum Sheet Heat Treatment

Molybdenum and Tungsten flat products are rolled and annealed to provide the optimum condition for the desired end use (Furnace, Punch, Deep Draw).

Below are a list of common molybdenum foil, sheet and plate sizes. Please call for availability, finish, and lengths or click below to visit our online store.

| Material | Format | Size Inches “ | Size MM |

| Molybdenum | Foil | 0.001 | 0.025 |

| Molybdenum | Foil | 0.002 | 0.050 |

| Molybdenum | Foil | 0.003 | 0.080 |

| Molybdenum | Foil | 0.004 | 0.100 |

| Molybdenum | Foil | 0.005 | 0.127 |

| Molybdenum | Foil / Sheet | 0.006 | 0.150 |

| Molybdenum | Foil / Sheet | 0.007 | 0.178 |

| Molybdenum | Foil / Sheet | 0.008 | 0.200 |

| Molybdenum | Foil / Sheet | 0.010 | 0.250 |

| Molybdenum | Sheet | 0.015 | 0.381 |

| Molybdenum | Sheet | 0.020 | 0.500 |

| Molybdenum | Sheet | 0.025 | 0.635 |

| Molybdenum | Sheet | 0.030 | 0.762 |

| Molybdenum | Sheet | 0.039 | 1.000 |

| Molybdenum | Sheet | 0.040 | 1.016 |

| Molybdenum | Sheet | 0.050 | 1.270 |

| Molybdenum | Sheet | 0.059 | 1.500 |

| Molybdenum | Sheet | 0.060 | 1.524 |

| Molybdenum | Sheet | 0.079 | 2.000 |

| Molybdenum | Sheet | 0.080 | 2.032 |

| Molybdenum | Sheet | 0.090 | 2.286 |

| Molybdenum | Sheet | 0.098 | 2.500 |

| Molybdenum | Sheet | 0.100 | 2.540 |

| Molybdenum | Sheet | 0.118 | 3.000 |

| Molybdenum | Sheet | 0.125 | 3.175 |

| Molybdenum | Sheet | 0.150 | 3.810 |

| Molybdenum | Sheet | 0.157 | 4.000 |

| Molybdenum | Sheet / Plate | 0.187 | 4.763 |

| Molybdenum | Plate | 0.197 | 5.000 |

| Molybdenum | Plate | 0.200 | 5.080 |

| Molybdenum | Plate | 0.250 | 6.350 |

| Molybdenum | Plate | 0.270 | 6.858 |

| Molybdenum | Plate | 0.300 | 7.620 |

| Molybdenum | Plate | 0.313 | 7.938 |

| Molybdenum | Plate | 0.375 | 9.525 |

| Molybdenum | Plate | 0.394 | 10.000 |

| Molybdenum | Plate | 0.410 | 10.414 |

| Molybdenum | Plate | 0.500 | 12.700 |

| Molybdenum | Plate | 0.591 | 15.000 |

| Molybdenum | Plate | 0.625 | 15.875 |

| Molybdenum | Plate | 0.750 | 19.050 |

| Molybdenum | Plate | 0.787 | 20.000 |

| Molybdenum | Plate | 1.000 | 25.400 |

| Molybdenum | Plate | 1.125 | 28.575 |

| Molybdenum | Plate | 1.187 | 30.150 |

| Molybdenum | Plate | 1.250 | 31.750 |

| Molybdenum | Plate | 1.375 | 34.925 |

| Molybdenum | Plate | 1.500 | 38.100 |

| Molybdenum | Plate | 1.750 | 44.450 |

| Molybdenum | Plate | 2.000 | 50.800 |

| Molybdenum | Plate | 2.500 | 63.500 |

| Molybdenum | Plate | 3.000 | 76.201 |

MOLYBDENUM:

High purity molybdenum possesses unique properties that are suitable for use in a number of applications and industries. For example, its high melting point, 2620 °C, drives its performance in high temperature environments. Elmet starts with the highest quality Mo powder to ensure our final product always meets our customer’s application needs. In addition, we will modify the manufacturing processes to meet even the most exacting application requirements that our customers have.

- Symbol: Mo

- Category: Transition Metal, Group VI

- Atomic Number: 42

- Density: 10.28 g / cm3

- Discovered: 1778

- High melting temperature, 2620 °C

- Low vapor pressure at high temperature

- Low coefficient of thermal expansion (CTE)

- Good thermal and electrical conductivity

- High density

- Good corrosion and creep resistance

- Load bearing capabilities at temperatures up to 2000 °C,

- Excellent thermal and electrical conductivity

- Shielding from high energy particles

Fully Integrated Tungsten and Molybdenum Manufacturing:

When tungsten and molybdenum material characteristics and properties must be critically controlled for superior end product performance, companies rely on Elmet Technologies unmatched expertise in the field of powder metallurgy. Our advanced powder processing produces pure tungsten and molybdenum metal powders as well as specific metal alloys. By selectively influencing aspects of the metallurgical process, we can change characteristics like porosity, strength, and temperature resistance to meet our customers specific needs. At Elmet, our process is fully integrated and starts with the raw material, metal oxide, which is then purified to tungsten and molybdenum metal powder through a chemical reduction process. The powder is formed into semi-finished products through a series of advanced mixing, pressing, deformation and heating technologies. Finished products are then carefully manufactured to customer specifications utilizing our state-of-the-art machining and fabrication techniques. By controlling each step in the production process from metal powder to finished product we ensure that our products consistently deliver the performance and quality required by our customers.

Precision Machining, Fabrication & Assembly:

Elmet also offers precision tungsten and molybdenum machining and fabrication capabilities. We’ve honed our processes during our decades of successfully working with molybdenum and tungsten. At our United States facilities, Elmet operates more than 70 machines that are dedicated to supporting your precision machining and fabrication requirements for molybdenum and tungsten.