Tungsten Heavy Alloy PRECISION MACHINING

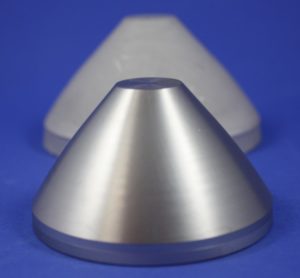

Tungsten Heavy Alloy (WHA) Machining. Leading companies purchase Elmet-made tungsten heavy alloy material for applications such as ballast weights, radiation shields, boring bars, ordnance components and other components requiring high density and good ductility.

With over 80 years of experience and formerly as part of the Royal Philips group, Elmet is a global leader in tungsten, tungsten heavy alloy and molybdenum refractory metal machining and fabrication. As technologies advance, component and assembly specifications become more stringent; machining and fabrication techniques must support demanding precision requirements and increasingly complex geometries.

At Elmet Technologies, we pride ourselves in offering our customers sophisticated WHA (tungsten heavy alloy) machining and fabrication capabilities that have been honed over decades of experience with two of the most challenging materials to machine: molybdenum and tungsten. We operate more than 70 machines dedicated to supporting your precision machining and fabrication requirements. Below is a brief list of some of our current capabilities. Please contact Elmet with your requirements for machining and fabrication.

Refractory Metal Machining

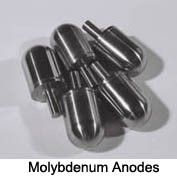

- Molybdenum (Mo) Machining

- TZM Machining

- Mo-La Machining

- Tungsten (W) Machining

- Tungsten Heavy Alloy Machining

- Tantalum Alloy Machining

- Lanthanum Alloy Machining

Equipment Capabilities

- CNC VMC (3-, 4-, and 5-axis), HMC (4-axis), Twin Spindle Lathe (3-axis), Swiss Screw (9-axis), and Bed Mill Machines

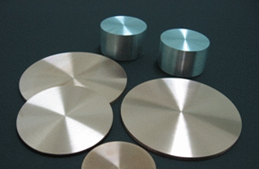

- Grinding, Lapping, and Polishing

- Threading

- EDM, Laser, Water Jet Cutting

- Gun drilling

- Spinning

- CMM, vision inspection, etc.

- And much more

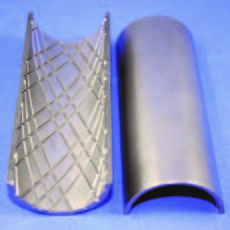

Fabrication & Assembly

- Welding, soldering, brazing

- Riveting

- Metal Forming, Folding and bending

- Punching and stamping

- Complex assembly

Examples of Fabricated Parts

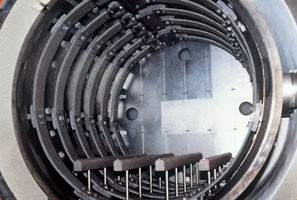

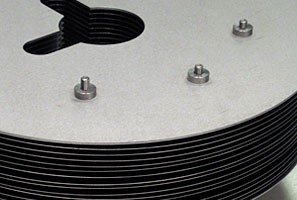

Furnace Components

Ion Implant Semiconductor Tool Parts

Silicon wafer processing relies on the use of ion implantation systems that inject ions at high energy directly into silicon wafer surfaces. The ion plasma source is energized via tungsten electrodes which operate within fabricated tungsten arc chamber.

Lamp Components

Sintering Boats and Carriers

CHEMICAL COMPOSITION AND AS-SINTERED MECHANICAL PROPERTIES

STANDARD WHA GRADES for Machining

Grade | ET90 | ET90NM | ET92.5 | ET92.5NM | ET93 | ET95 | ET95NM | ET97 |

ASTM B-777 | Class 1 | Class 1 | Class 2 | Class 2 | – | Class 3 | Class 3 | Class 4 |

| AMS 7725E | Class 1 Type 2 | Class 1 Type 1 | Class 2 Type 2 | Class 2 Type 1 | – | Class 3 Type 2 | Class 3 Type 1 | Class 4 Type 2 |

MIL-T-21014D | Class 1 | Class 1 | Class 2 | Class 2 | – | Class 3 | Class 3 | Class 4 |

| W content, wt.% | 90 | 90 | 92.5 | 92.5 | 93 | 95 | 95 | 97 |

Ni content, wt.% | 7.0 | 8.9 | 5.3 | 6.7 | 5.6 | 3.5 | 4.4 | 2.1 |

| Fe content, wt.% | 3.0 | 1.1 | 2.2 | 0.8 | 1.4 | 1.5 | 0.6 | 0.9 |

Density, g/cm3 | 17.0 | 17.0 | 17.5 | 17.5 | 17.7 | 18.0 | 18.0 | 18.5 |

| UTS, ksi | ≥ 110 | ≥ 110 | ≥ 110 | ≥ 110 | ≥ 110 | ≥ 105 | ≥ 105 | ≥ 100 |

UTS, MPa | ≥ 758 | ≥ 758 | ≥ 758 | ≥ 758 | ≥ 758 | ≥ 724 | ≥ 724 | ≥ 689 |

| YS, ksi | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 |

YS, MPa | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 |

| Elongation, % | ≥ 5 | ≥ 5 | ≥ 5 | ≥ 5 | ≥ 5 | ≥ 3 | ≥ 3 | ≥ 2 |

Hardness, HRC | ≤ 32 | ≤ 32 | ≤ 33 | ≤ 33 | ≤ 33 | ≤ 34 | ≤ 34 | ≤ 35 |

| Mag. perm. | > 1.05 | ≤ 1.05 | > 1.05 | ≤ 1.05 | > 1.05 | > 1.05 | ≤ 1.05 | > 1.05 |

Critical Note:

- Other alloy compositions and properties may be available as a special order

- All WHA products are compliant with EU RoHS Directive 2002/95/EC, 2011/65/EU and with REACH Regulation (EC) No. 1907/2006

- All WHA defense products are compliant with section 871 of the FY2019 National Defense Authorization Act, codified at 10 U.S.C. 2533c, and the January 28, 2019 acquisition directive from the Office of the Under Secretary of Defense. Click here for a link to the NDAA guidance.

- All raw materials for Elmet’s WHA rod products are obtained from certified conflict-free sources

STANDARD PRODUCT SIZES

Blocks, sintered | 6.0” x 4.8” x 2.3” 4.6” x 3.4” x 2.1” 7.0” x 2.3” x 2.0” 6.0” x 1.5” x 1.5” | 150 mm x 120 mm x 57 mm 120 mm x 86 mm x 54 mm 180 mm x 58 mm x 51 mm 150 mm x 39 mm x 38 mm |

Rods, sintered | 0.5 to 1.0” in diameter Lengths up to 24” | 12.7 to 25.4 mm in diameter Lengths up to 610 mm |

Rods, swaged | 0.25 to 1.0” in diameter Lengths up to 48” | 6.35 to 25.4 mm in diameter Lengths up to 1219.2 mm |

Plate, hot rolled | 0.25 to 1.0” in thickness Widths and lengths up to 24” | 6.35 to 25.4 mm in thickness Widths and lengths up to 610 mm |

Note: other sizes and properties available as special order