Tungsten Heavy Alloy Rod Material

Tungsten Heavy Alloy Rod Material. Elmet is a 100% US owned, fully integrated, leading producer of high-quality tungsten heavy alloy rod material. Elmet is ISO, AS9100, and ITAR registered and a qualified supplier to many Tier 1/2 aerospace and defense contractors that leverage our specialty tungsten material as balance weights, flight hardware, and munition subcomponents. Our tungsten heavy alloy meets all ASTM B-777 and MIL-T-21014D requirements.

Elmet Technologies presses and sinters high-quality tungsten heavy alloy (WHA) rods that can then be further swaged by Elmet to produce rods with ultimate tensile strengths exceeding 180 ksi (1240 MPa) and elongations exceeding 5%. Elmet also precision machines WHA rods for use as ballast weights, radiation shields, boring bars, ordnance components, and other components that require high density and good ductility.

WHA Hot Swaged Rods with Enhanced Mechanical Properties

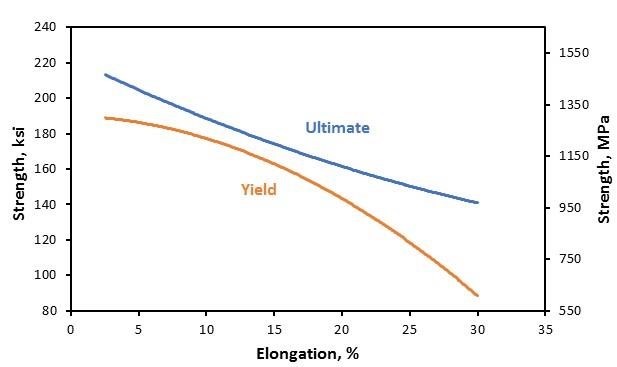

Elmet is a leader of providing Tungsten Heavy Alloy (WHA) hot swaged rod material with enhanced properties. Elmet can adjust swaging and heat-treating conditions to produce WHA rods with specific combinations of strength and ductility.

Swaged Rods are produced in diameters <.25” to >1” based on customer requirements.

Pressed & Sintered WHA B-777 Rod Sizes:

If advanced swaging is not required Elmet also has a number of standard rod molds for pressing and sintering material. Below are several commonly pressed and sintered heavy alloy sizes.

- 0.720” x 26” rod Tungsten Heavy Alloy ASTM B-777 machining blank

- 0.490” x 26” rod Tungsten Heavy Alloy ASTM B-777 machining blank

Please contact Elmet to see what inventory is in stock or to discuss your application and any mill run minimum order sizes that might exist.

CHEMICAL COMPOSITION AND AS-SINTERED MECHANICAL PROPERTIES

STANDARD WHA GRADES

Grade | ET90 | ET90NM | ET92.5 | ET92.5NM | ET93 | ET95 | ET95NM | ET97 |

ASTM B-777 | Class 1 | Class 1 | Class 2 | Class 2 | – | Class 3 | Class 3 | Class 4 |

| AMS 7725E | Class 1 Type 2 | Class 1 Type 1 | Class 2 Type 2 | Class 2 Type 1 | – | Class 3 Type 2 | Class 3 Type 1 | Class 4 Type 2 |

MIL-T-21014D | Class 1 | Class 1 | Class 2 | Class 2 | – | Class 3 | Class 3 | Class 4 |

| W content, wt.% | 90 | 90 | 92.5 | 92.5 | 93 | 95 | 95 | 97 |

Ni content, wt.% | 7.0 | 8.9 | 5.3 | 6.7 | 5.6 | 3.5 | 4.4 | 2.1 |

Fe content, wt.% | 3.0 | 1.1 | 2.2 | 0.8 | 1.4 | 1.5 | 0.6 | 0.9 |

Density, g/cm3 | 17.0 | 17.0 | 17.5 | 17.5 | 17.7 | 18.0 | 18.0 | 18.5 |

UTS, ksi | ≥ 110 | ≥ 110 | ≥ 110 | ≥ 110 | ≥ 110 | ≥ 105 | ≥ 105 | ≥ 100 |

UTS, MPa | ≥ 758 | ≥ 758 | ≥ 758 | ≥ 758 | ≥ 758 | ≥ 724 | ≥ 724 | ≥ 689 |

YS, ksi | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 |

YS, MPa | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 |

Elongation, % | ≥ 5 | ≥ 5 | ≥ 5 | ≥ 5 | ≥ 5 | ≥ 3 | ≥ 3 | ≥ 2 |

Hardness, HRC | ≤ 32 | ≤ 32 | ≤ 33 | ≤ 33 | ≤ 33 | ≤ 34 | ≤ 34 | ≤ 35 |

Mag. perm. | > 1.05 | ≤ 1.05 | > 1.05 | ≤ 1.05 | > 1.05 | > 1.05 | ≤ 1.05 | > 1.05 |

Critical Note:

- Other alloy compositions and properties may be available as a special order

- All WHA products are compliant with EU RoHS Directive 2002/95/EC, 2011/65/EU and with REACH Regulation (EC) No. 1907/2006

- All WHA defense products are compliant with section 871 of the FY2019 National Defense Authorization Act, codified at 10 U.S.C. 2533c, and the January 28, 2019 acquisition directive from the Office of the Under Secretary of Defense. Click here for a link to the NDAA guidance.

- All raw materials for Elmet’s WHA rod products are obtained from certified conflict-free sources

All Elmet Tungsten Heavy Alloy (WHA) rods are pressed, sintered and if needed swaged and cut to size to customer specified thickness, length, surface finish as well as other material properties. We also offer high volume, precision machining, threading, and gun-drilling services. As with all of our materials, our rod begins as metal powder, pressed into ingots, sintered, and then swaged and drawn down. Our advanced drawing / swaging process enables us to tailor the product to meet specific customer material and performance requirements to ensure optimal performance in your application.

MORE INFORMATION:

Please contact one of our application specialists at 1.800.343.8008 to find out more about our tungsten heavy alloy rod capabilities and sizes.