ASTM B777 Class 3 Tungsten Heavy Alloy

Elmet Technologies ASTM B777 Class 3 Tungsten Heavy Alloy specification overview. This guide will help you understand the advantages, materials, applications, technical data and the common sizes of WHA Class 3 Elmet Technologies manufactures. This provides our clients with a deep understanding of ASTM B777 Class 3 WHA.

Overview

What is ASTM B777 Class 3 tungsten heavy alloy? Pure Tungsten (also known as “Wolfram”) is an element first discovered in 1781. It is represented on the periodic table with symbol W, with atomic number 74. Pure tungsten (W) is not the same thing as what is commonly referred to as tungsten alloys, tungsten heavy alloys or WHA. According to ASTM B777 there are four (4) classes of tungsten heavy alloys, namely class 1, class 2, class 3, and class 4. In this section, we’ll examine ASTM B777, Class 3.

ASTM B777 Class 3 Properties

Class 3 WHA material contains nominally, 95 weight percent (wt.%) Tungsten (W). Elmet’s Class 3 products are designated as ET95 and ET95NM. ASTM B777 WHA, Class 3 provides a very high density material that is easier to produce and machine relative to pure tungsten. It is often used for X-Ray, radiation and other medical shielding applications. Class 3 material starts out as a blended metal powder (Pure W mixed with a binder of Ni and Iron).

Then the material is pressed and sintered. In some cases, it is machined into high quality tungsten heavy alloy (WHA) blocks, rods, and shaped parts. Class 3 has lower density compared to Pure Tungsten or Class 4. However, it offers increased density over Class 1 and Class 2. Similarly, it provides over twice the density of steels and most nickel-based super alloys. Class 3 elongation can be further improved (additional fraction resistance) by specialized post-sintering heat treatment.

Benefits of WHA Material

Class 3 WHA (ET95), is only used when the properties of Class 1 or 2, for some reason, cannot offer sufficient density or shielding capability. Class 3 non mag (NM) is commonly selected when a combination of low magnetic permeability and considerable attenuation is required. While still machinable, Class 3 is more difficult to machine than Class 1 or Class 2.

The advantages and benefits of using WHA material includes:

- Environmental and density advantages over lead for radiation shielding

- Unique capabilities for vibration dampening and balance weight applications

- Ideal for applications requiring very high density

- Often leveraged in defense applications for its unique combination of YS, elongation and density

- Excellent ability to absorb gamma rays and x-rays

- Comparatively, improved machinability as compared to Class 4 or pure tungsten

ASTM B777 Class 3 WHA Specifications & Data

The below table highlights the properties of the Class 3 tungsten alloys (for both low mag and non mag), including mechanical properties. The ASTM B777, AMS 7725, and legacy AMS and MIL-T-21014 Class 3 nominal compositions and properties are:

| GRADE | ET95 | ET95NM |

ASTM B-777 | Class 3 | Class 3 |

AMS 7725E | Class 3 Type 2 | Class 3 Type 1 |

MIL-T-21014D | Class 3 | Class 3 |

W content, wt.% | 95 | 95 |

Ni content, wt.% | 3.5 | 4.4 |

Fe content, wt.% | 1.5 | 0.6 |

Density, g/cm3 | 18 | 18 |

UTS, ksi | ≥ 105 | ≥ 105 |

UTS, MPa | ≥ 724 | ≥ 724 |

YS, ksi | ≥ 75 | ≥ 75 |

YS, MPa | ≥ 648 | ≥ 648 |

Elongation, % | ≥ 3 | ≥ 3 |

Hardness, HRC | ≤ 34 | ≤ 34 |

Mag. perm. | > 1.05 | ≤ 1.05 |

Sizes of WHA Class 3 Material

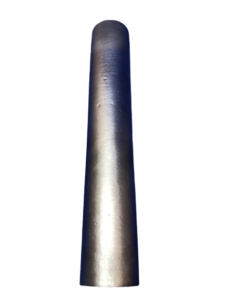

Elmet has a large and growing inventory of standard mold sizes which further help shorter lead-times. In addition, special tooling can be made for matching the exact size needed for a project. All sizes can be sold “rough as sintered” or machined to provide tighter tolerances. Elmet also precision machines WHA parts for use as ballast weights, radiation shields, boring bars, ordnance components. Additionally, we manufacture other Class 3 WHA components that require domestically sourced tungsten alloys.

Elmet Technologies: Your Partner for WHA

Elmet’s world-class manufacturing facilities fabricate WHA to our global customers most exacting specifications. With years of experience manufacturing solutions for the most demanding tungsten heavy alloy applications, our highly qualified team at Elmet Technologies provides you with the knowledge and expertise required for your success.

To discuss your ASTM B777 Class 3 Tungsten Heavy Alloy (WHA) requirements, please contact us at [email protected]