Thermal Spray Powders

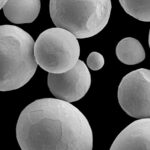

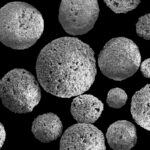

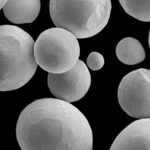

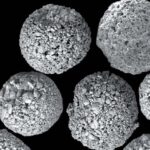

Elmet Technologies is a leading manufacturer of thermal spray powders using high-quality molybdenum and various other alloy powder products. Our molybdenum thermal spray powders are spherical, flowable and designed to improve and restore surfaces from large area coatings to small metal components.

These powder metallurgy products involve the disposition of powders covering a substrate forming an even coating of contiguous layers protecting the substrate that wouldn’t otherwise survive in its harsh environment.

Our Diverse Spraying Processes

Innovation is key to Elmet’s success in developing the highest quality molybdenum and tungsten products for thermal spray applications. Our diverse spraying processes for thermal spray powders includes:

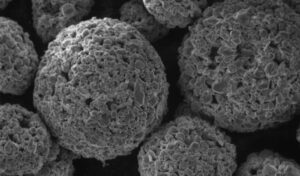

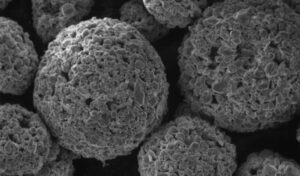

Spray Dried Powder Spherical and Flowable

- Plasma

- Flame

- Detonation

- High velocity air fuel (HVAF)

- High velocity oxy-fuel coating spraying (HVOF)

We can also alloy with carbon to produce any level of C content up to 6% (pure Mo₂C).

Additional customized alloy powder products are available upon request.

Common Applications

Common applications include engine parts for popular transportation modes. This includes automobiles, trains, aircraft and boats. In addition, many applications that are subject to usage and environmental effects, such as: chemical plants, food manufacturing and packaging, mining, earthmoving equipment, and power generation, where erosion, wear and corrosion are common, also benefit from the usage of thermal spray powders.

Materials and Specifications

Pure molybdenum powder for various size specifications:

- Coarse Grade -170+325 mesh

- PWA 1313 -200+325

- Finest – PWA 1338

- Fine Grade -325 mesh

Chemical Characteristics¹

Mo (excluding gases) min. 99.8%

¹Mass fraction in % [cg/g]; ppm [μg/g]

Physical Characteristics

Apparent Density 30 g/cubic inch minimum

Hall flow 35 s/50 g maximum

Molybdenum Thermal Spray Powders (PDF)

Packaging

The molybdenum powder is shipped in non-returnable polyethylene-line 20 liter (5 gallon) plastic pails or 60 liter (15 gallon) steel drums. Special packaging inquiries welcome.

The Elmet Advantage: High-Performance Spray Powders

As global leaders in the development and manufacture of thermal spray powders, Elmet offers one of the most comprehensive and robust product portfolios in the powder metallurgy industry.

Our quality-assured materials development and processing capabilities ensure that high-performance powders can be generated to specific customer requirements with exceptional material properties.

This includes: irregular or spherical powder morphology with tight control of particle size distributions (PSDs); high reproducibility; and outstanding purity levels.

We can customize key particle properties based on unique customer specifications and can generate quantities from the lab-scale up to high volume automated manufacturing. Additionally, the Elmet Technologies team is available to assist with R&D services for custom high-performance powders and alloys.

To discuss your spray powder requirements, please contact our team of dedicated applications experts today.