Tungsten Heavy Alloy (WHA)

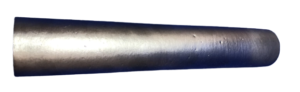

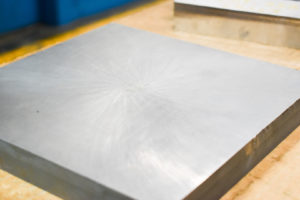

Elmet manufactures Tungsten Heavy Alloy (WHA) in various forms, including blocks, rods, and other shaped parts. Our manufacturing and machining capabilities allow us to offer Tungsten Heavy Alloy in ASTM B777 Class 1, 2, 3 and 4. Elmet’s high-quality pressing and sintering processes enable our large inventory of standard tungsten heavy alloy (WHA) molds and sizes to continue to grow. The WHA manufactured by Elmet Technologies is sold either “rough as sintered,” or alternatively, precision machined to provide tighter tolerances.

ASTM B777: Tungsten Heavy Alloy

ASTM B777 is a standard specification for Tungsten Heavy Alloys (WHA). The specification is organized into four classes (1-4). Each categorization or classification represents a percentage amount of Tungsten (W) Alloy. For more detailed specification on ASTM B777 & AMS 7725, we welcome you to check out this in-depth overview. Below is a brief outline of each class (1-4).

ASTM B777 Classification | Percent Tungsten (W) Alloy | Overview |

Class 1: | 90 % | |

Class 2: | 92.5 % | |

Class 3: | 95 % | |

Class 4: | 97.5 % |

Applications for WHA

The applications for WHA are extensive. Elmet precision machines tungsten heavy alloy parts for use as ballast weights, radiation shields, boring bars, ordnance components and other applications which require high density and superior ductility.

Where is WHA used?

Most commonly, WHA is used in applications requiring counterweights, inertial masses, radiation shielding, and ordnance products, as well as a number of other applications.

Mostly due to its strength, density and weight, WHA is a preferable metal for applications in which a balance weight is required. This includes turbines, crankshafts, and helicopter rotors, among others.

Likewise, WHA is utilized in commercial & military aircraft, spacecraft, mobile & stationary defense vehicles & transportation systems, as well as warheads, munitions and fragmentation.

Learn more about WHA for Aerospace & Defense Applications

WHAs are ideal for X-ray shielding applications in the medical industry. The alloying of tungsten makes it easier for Elmet to produce the complex shapes and forms design engineers developed for critical medical devices & technologies. Typical applications for tungsten heavy alloy in the medical industry includes CT & imaging technologies, nuclear medicine shielding, and surgical robots, among others.

Learn how WHA is engaged in Medical Shielding & X-Ray Imaging Applications

Why choose WHA?

Typically, WHA is used in settings where strength, high density and weight are required. However, it is not for every application given its high cost. Typically, tungsten is only used in highly specialty applications demanding one of its unique properties.

To learn more about its applications, history and factors to consider when choosing tungsten heavy alloy, we welcome you to visit this resource page.

Benefits of Tungsten Heavy Alloy

The benefits of Tungsten Heavy Alloy center around its high density properties. While it is ideal for applications requiring very high density, it also serves environmental benefits over lead for radiation shielding. Two unique capabilities of Tungsten Heavy Alloy are (1) its ability to dampen vibration, and (2) its ability to serve in applications requiring a balance weight. For defense applications, WHA offers benefits in terms of its distinctive combination of YS, elongation and density.

Additionally, it is beneficial in the sense that it has an excellent ability to absorb gamma rays and x-rays. When comparing heavy alloy to pure tungsten, WHA has improved machinability as well. In summation, the many benefits of WHA are attributable to its excellent mechanical properties for unique applications.

Tungsten Heavy Alloys: Low Mag vs. Non Mag

If you are in the processing of considering utilizing Tungsten Alloy materials, there is a good chance you are curious about low mag vs. non mag options. These, of course, are “magnetic” and “non-magnetic” – but we like to think of them as low mag and non-mag. In consideration of the options, you may be curious: which type is best for my application? We’ve put together an analysis of the options – and describe use cases for each, as well as the benefits, among other factors to consider. Learn more about low mag vs. non mag options.

Buy WHA Online

Here at Elmet, we offer a convenient way to purchase WHA online. The Elmet eCommerce Online Store offers WHA bars (as sintered) and WHA blocks (as sintered or machined) in a range of sizes. Alternatively, you can reach out to our customer support team to inquire about our other WHA products. Elmet offers more than 2,000 different product/sizes. Our eCommerce Online Store merely represents a short list of items we try to always have in stock. Please contact an Elmet support specialist to discuss your requirements.

This includes plates, sheets, rods, disks, and more. To view our standard catalog and data for WHA products, please see Elmet Technologies WHA Standard Sizes & Material Data Sheet

Elmet Technologies: Your Partner in Tungsten Heavy Alloy

For over 90 years, Elmet Technologies industry-leading expertise in performance metals allows us to continually grow our inventory of standard molds and sizes. Our capabilities with tungsten heavy alloy continue to grow. To learn more about Elmet, or to discuss your project – contact the experts at [email protected].

All products comply with: DFARS 252.225-7001 Buy American Act; DFARS 252.225-7009 Specialty Metals; DFARS 252.225-7052 Magnets and Tungsten. All products are compliant with EU RoHS Directive 2015/863 and with Regulation (EC) No. 1907/2006 of The European Parliament and of the Council concerning the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH). Mercury or mercury-containing compounds were not intentionally added or came in direct contact with hardware or supplies furnished under this purchase order. Pursuant to Section 1502 (“the Provision”) of the Dodd-Frank Wall Street Reform and Consumer Protection Act (“Act”) (Pub. L. 111-203, 124 Stat. 1376, July 21, 2010), also referred to as the “Conflict Minerals Act”, Elmet Technologies only purchases “DRC conflict-free” minerals from smelters on the Conflict-Free Smelter Program (CFSP) Compliant Smelter list.

Learn more about DFARS compliant tungsten and WHA.

Learn about the latest DoD regulations and restrictions on foreign sources of supply.