ASTM B777 – AMS 7725 Overview

Elmet Technologies ASTM B777 – AMS 7725 Overview provides an in-depth analysis of the specifications for Elmet’s Tungsten Heavy Alloys. To discuss ASTM B777 or AMS 7725 requirements, contact [email protected].

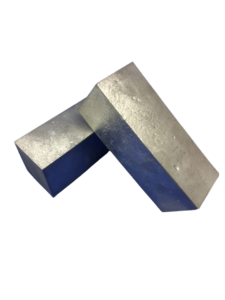

Elmet produces a full range of tungsten heavy alloys to meet our customer’s requirements and industrial specifications. Below is an engineering guide as it relates to the ASTM and AMS specifications covering some of our materials. Industry standards are critical for tungsten heavy alloy application development, material specification, procurement. They are also important for managing long term material quality and consistency.

About ASTM B777 & AMS 7725

ASTM B777 “Standard Specification for Tungsten Base, High-Density Metal” and AMS 7725, “Tungsten Heavy Alloy Shapes, Sintered, High Density” both define 4 classes of tungsten alloys containing nominally, 90 to 97 weight percent (wt%) Tungsten (W). These four classes are pressed, sintered, and and in some cases annealed into shapes.

Classes 1-3 are commonly available as non-magnetic and magnetic, while Class 4 is typically only available with a magnetic composition. Outside of ASTM Elmet also offers a “modified Class 2” composition which is 93% weight percent (wt%) Tungsten (W) and has some enhanced properties for certain defense applications.

ASTM vs. AMS – Specifications

The ASTM and AMS specifications differ slightly with regards to the differentiation of magnetic and non-magnetic call outs. AMS7725 defines non-magnetic alloys as Type 1, and magnetic alloys are Type 2. Additionally, the AMS specification states, if no Class is specified Class 1 shall be supplied and if no Type is specified, Type 2 shall be supplied.

Other differences between ASTM and AMS specifications: AMS 7725 has a special configuration called “Sintered and Annealed”. When customers require enhanced elongation performance or for others reasons sometimes a drawing will specify “and annealed”. This then MUST include an extra vacuum anneal step. If just “as-sintered” is specified then no vacuum anneal needed. ASTM specifications do not clarify these two different levels of heat treating.

About MIL-T-21014

MIL-T-21014, “Tungsten Base Metal, High Density” also defines the 4 tungsten alloy classes in a similar manner to the ASTM & AMS specifications previously mentioned. However, MIL-T-21014D NOTICE 1, dated October 5th, 1998 states: MIL-T-21014D, dated 22 August 1986, with Amendment 1, dated 14 November 1991, is hereby cancelled.

Future acquisition of this item should refer to SAE-AMS-T-21014, “Tungsten Base Metal, High Density.” And as of March 2008, SAE has declared SAE-AMS-T-21014, “Canceled” and superseded by ASTM B777. That said, many legacy documents still refer to MIL-T-21014D specifications. When possible, it is best for drawings to be updated to the latest specifications.

What does all that mean? Unless sourcing Class 1-4 tungsten for legacy hardware where the drawing has not been updated since prior to the aforementioned (canceled) documents, the MIL and SAE-AMS-T-21014 specification should not be cited on a drawing as it is no longer considered an active standard. Citing ASTM B777 or AMS 7725 as an alternative material would be proper.

Non-Magnetic & Magnetic Differences between ASTM B777 & AMS 7725

B777 states Class 4 is not available in a non-magnetic condition. Common magnetic tungsten alloys contain a binder of transition metals such as nickel and iron. Common non-magnetic tungsten alloys contain similar binders and transition metals but require a lower ratio of iron or an alternative. Non-magnetic tungsten alloys are commonly defined as those having a maximum magnetic permeability of 1.05 Mu and is verified by the test method defined in ASTM A342.

Example drawing note/call out:

- Material: Tungsten Class 1 per ASTM B777

- Alternative Material: Tungsten Class 1, Type 2 per AMS7725.

Both the ASTM and AMS documents are periodically revised to maintain current and relevance with continuous improvements across the supplier base. In fact, Elmet staff has from time to time been part of the committees responsible for maintaining these documents.

For reference: ASTM B777 specification is under the jurisdiction of ASTM Committee B10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of Subcommittee B10.04 on Molybdenum and Tungsten. AMS 7725 is prepared by AMS Committee G, Titanium and Refractory Metals Committee.

Testing Differences between ASTM & AMS:

It is important for customers to understand the testing differences between these specifications. The testing differences between ASTM B777 and AMS 7725 are as follows:

ASTM B777

- One set of tests approves powder lot for all orders, all later sintering batches.

- All tensile tests done with standard test bar (not necessary from a part or from a piece of material that is the same size as the part being orders)

- Vacuum Annealing is not specified or required as part of ASTM B777

- Standard for all Elmet products and in cases where customers ask for obsolete MIL-T-21014

- What resellers of China material will typically stock in the US since it is lower cost and easier to meet and stock in a variety of sizes.

AMS 7725

- With AMS 7725, producers like Elmet must test each powder lot and sintering lot combination

- Tensile test blank must be from actual part or test bar of same thickness as part

- If ordered as “Sintered and Annealed” – MUST also include a vacuum anneal. If just “as-sintered” then no vacuum anneal is needed.

- Can offer enhanced properties such as increased elongation if specified with the added anneal step.

- More expensive per piece vs. ASTM given the added test and material costs

- For the most stringent applications, the AMS spec will provide more assurances to customers.

- It is critical to understand if buying from a stocking reseller if AMS can be met (often can not).

- One set of tests approves powder lot for all orders, all later sintering batches.

- All tensile tests done with standard test bar, easy to pass

- Vacuum Annealing not required (although we need to if we need to swage or roll)

ASTM B 777 and AMS 7725 – Technical Data

The table below outlines the mechanical and physical properties of the four different classes of tungsten alloys (both magnetic and non-magnetic). Elmet’s tungsten heavy alloys are the leading source for customers demanding the highest quality domestic US source.

Also, check the properties of each tungsten class in the table below to determine the alloy which suits your needs best. Furthermore, do not hesitate to contact our customer support team for your further inquiries!

STANDARD GRADES

| Grade | ET90 | ET90NM | ET92.5 | ET92.5NM | ET93 | ET95 | ET95NM | ET97 |

| ASTM B-777 | Class 1 | Class 1 | Class 2 | Class 2 | – | Class 3 | Class 3 | Class 4 |

| AMS 7725E | Class 1 Type 2 | Class 1 Type 1 | Class 2 Type 2 | Class 2 Type 1 | – | Class 3 Type 2 | Class 3 Type 1 | Class 4 Type 2 |

| MIL-T-21014D | Class 1 | Class 1 | Class 2 | Class 2 | – | Class 3 | Class 3 | Class 4 |

| W content, wt.% | 90 | 90 | 92.5 | 92.5 | 93 | 95 | 95 | 97 |

| Ni content, wt.% | 7.0 | 8.9 | 5.3 | 6.7 | 5.6 | 3.5 | 4.4 | 2.1 |

| Fe content, wt.% | 3.0 | 1.1 | 2.2 | 0.8 | 1.4 | 1.5 | 0.6 | 0.9 |

| Density, g/cm3 | 17.0 | 17.0 | 17.5 | 17.5 | 17.7 | 18.0 | 18.0 | 18.5 |

| UTS, ksi | ≥ 110 | ≥ 110 | ≥ 110 | ≥ 110 | ≥ 110 | ≥ 105 | ≥ 105 | ≥ 100 |

| UTS, MPa | ≥ 758 | ≥ 758 | ≥ 758 | ≥ 758 | ≥ 758 | ≥ 724 | ≥ 724 | ≥ 689 |

| YS, ksi | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 |

| YS, MPa | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 |

| Elongation, % | ≥ 5 | ≥ 5 | ≥ 5 | ≥ 5 | ≥ 5 | ≥ 3 | ≥ 3 | ≥ 2 |

| Hardness, HRC | ≤ 32 | ≤ 32 | ≤ 33 | ≤ 33 | ≤ 33 | ≤ 34 | ≤ 34 | ≤ 35 |

| Mag. perm. | > 1.05 | ≤ 1.05 | > 1.05 | ≤ 1.05 | > 1.05 | > 1.05 | ≤ 1.05 | > 1.05 |

In addition, other alloy compositions and properties may be available as special order

Elmet Technologies: Your Edge in Performance Metals

All products comply with: DFARS 252.225-7001 Buy American Act; DFARS 252.225-7009 Specialty Metals; DFARS 252.225-7052 Magnets and Tungsten. All products are compliant with EU RoHS Directive 2015/863 and with Regulation (EC) No. 1907/2006 of The European Parliament and of the Council concerning the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH). Mercury or mercury-containing compounds were not intentionally added or came in direct contact with hardware or supplies furnished under this purchase order. Pursuant to Section 1502 (“the Provision”) of the Dodd-Frank Wall Street Reform and Consumer Protection Act (“Act”) (Pub. L. 111-203, 124 Stat. 1376, July 21, 2010), also referred to as the “Conflict Minerals Act”, Elmet Technologies only purchases “DRC conflict-free” minerals from smelters on the Conflict-Free Smelter Program (CFSP) Compliant Smelter list.

WHA defense products are compliant with section 871 of the FY2019 National Defense Authorization Act, codified at 10 U.S.C. 2533c, and the January 28, 2019 acquisition directive from the Office of the Under Secretary of Defense.

To learn more about ASTM B777, AMS 7725, or to inquire about Elmet’s products, please contact us at [email protected]