Tungsten Heavy Alloy Product Data Sheet

To download Elmet Technologies’ Tungsten Heavy Alloy (WHA) product data sheet, click below for the PDF.

Elmet Technologies presses and sinters high quality tungsten heavy alloy (WHA) blocks, rods, and shaped parts. All material is made in the USA at Elmet’s fully integrated facility in Lewiston, Maine. Elmet has a large and growing inventory of standard molds and sizes that can be sold “rough as sintered” or machined to provide tighter tolerances. Sintered WHA blanks can be further rolled or swaged by Elmet to produce plates, sheets, and rods with ultimate tensile strengths exceeding 180 ksi (1240 MPa) and elongations exceeding 5%. Elmet also precision machines WHA parts for use as ballast weights, radiation shields, boring bars, ordnance components, and other components that require high density and good ductility.

Chemical Composition & As-Sintered Mechanical Properties

Standard Grades

Grade | ET90 | ET90NM | ET92.5 | ET92.5NM | ET93 | ET95 | ET95NM | ET97 |

ASTM B-777 | Class 1 | Class 1 | Class 2 | Class 2 | – | Class 3 | Class 3 | Class 4 |

AMS 7725E | Class 1 Type 2 | Class 1 Type 1 | Class 2 Type 2 | Class 2 Type 1 | – | Class 3 Type 2 | Class 3 Type 1 | Class 4 Type 2 |

MIL-T-21014D | Class 1 | Class 1 | Class 2 | Class 2 | – | Class 3 | Class 3 | Class 4 |

W content, wt.% | 90 | 90 | 92.5 | 92.5 | 93 | 95 | 95 | 97 |

Ni content, wt.% | 7.0 | 8.9 | 5.3 | 6.7 | 5.6 | 3.5 | 4.4 | 2.1 |

Fe content, wt.% | 3.0 | 1.1 | 2.2 | 0.8 | 1.4 | 1.5 | 0.6 | 0.9 |

Density, g/cm3 | 17.0 | 17.0 | 17.5 | 17.5 | 17.7 | 18.0 | 18.0 | 18.5 |

UTS, ksi | ≥ 110 | ≥ 110 | ≥ 110 | ≥ 110 | ≥ 110 | ≥ 105 | ≥ 105 | ≥ 100 |

UTS, MPa | ≥ 758 | ≥ 758 | ≥ 758 | ≥ 758 | ≥ 758 | ≥ 724 | ≥ 724 | ≥ 689 |

YS, ksi | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 |

YS, MPa | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 | ≥ 648 |

Elongation, % | ≥ 5 | ≥ 5 | ≥ 5 | ≥ 5 | ≥ 5 | ≥ 3 | ≥ 3 | ≥ 2 |

Hardness, HRC | ≤ 32 | ≤ 32 | ≤ 33 | ≤ 33 | ≤ 33 | ≤ 34 | ≤ 34 | ≤ 35 |

Mag. perm. | > 1.05 | ≤ 1.05 | > 1.05 | ≤ 1.05 | > 1.05 | > 1.05 | ≤ 1.05 | > 1.05 |

*Other alloy compositions and properties may be available as special order

All WHA products are compliant with EU RoHS Directive 2002/95/EC, 2011/65/EU and with REACH Regulation (EC) No. 1907/2006

All WHA defense products are compliant with section 871 of the FY2019 National Defense Authorization Act, codified at 10 U.S.C. 2533c, and the January 28, 2019 acquisition directive from the Office of the Under Secretary of Defense

All raw materials for Elmet’s WHA rod products are obtained from certified conflict-free sources.

Capabilities for Custom Sized WHA Material

| Blocks, sintered | Other sizes with up to 6” to 7” in Width and Height are available with a special mold fee Lengths up to >24” are possible (larger sizes can be limited by weight) The length dimension of some standard mold sizes (above) can be easily reduced. It is possible to cut/slice standard sizes into smaller pieces (added cutting fee) |

| Rods, sintered | 0.625 to 4.0” in diameter is possible with special mold fee. Lengths up to 24” are possible. |

| Rods, swaged | 0.25 to 1.0” in diameter Lengths up to 48” (30” is common for swaged rod) 3/8” and 1/2” swaged rods are often in stock |

Plate, hot rolled | 0.25 to 1.0” in thickness Widths and lengths up to 24” Standard sizes include: .125” thick plate 7” x 7” or 12” x 12” .250” thick plate 7” x 7” or 12” x 12” .50” thick plate 7” x 7” or 12” x 12” It is possible to cut/slice standard sizes into smaller pieces (added cutting fee) |

Disks, sintered | Elmet has several standard disk sizes available: Disk – 5.1″ diameter x 1.65″ tall with tolerances of +/-.125” Disk – 3.87″ diameter x 1.25″ tall with tolerances of +/-.125” 5.25″ diameter x 1.65″ tall x 0.925″ diameter hole with tolerances of +/-.125” 4.1″ diameter x 1.31″ tall x 1.25″Dia hole with tolerances of +/-.125” |

Standard Lead Times

Rough As Sintered – Standard Sizes | Class 1 Type 2 (ET90) and Class 2 Type 2 (ET92.5) – 3-4 weeks Class 3, Class 4 and all non mag blends – 6-7 weeks |

Ground Finish – Standard Sizes | Class 1 Type 2 (ET90) and Class 2 Type 2 (ET92.5) – 8-9 weeks Class 3, Class 4 and all non mag blends – 9-10 weeks |

Rough As Sintered – New Size / Mold | Class 1 Type 2 (ET90) and Class 2 Type 2 (ET92.5) – 9-10 weeks Class 3, Class 4 and all non mag blends – 10-11 weeks |

Ground Finish – New Size / Mold | Class 1 Type 2 (ET90) and Class 2 Type 2 (ET92.5) – 10-11 weeks Class 3, Class 4 and all non mag blends – 11-12 weeks |

Prices

Elmet Technologies’ WHA pricing is subject to change based on raw material markets and other factors. Please contact your Elmet sales representative or the factory for confirmation of the latest pricing and lead-times. Please refer to the Elmet Technologies WHA product data sheet for pricing details.

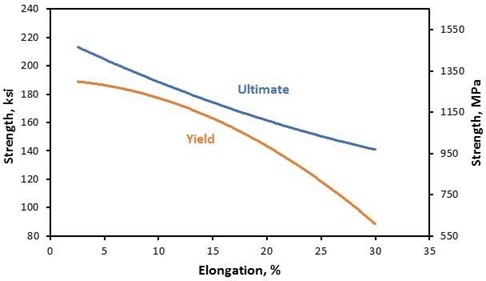

As-Swaged WHA Rod Mechanical Properties

Elmet Technologies can adjust swaging and heat-treating conditions to produce WHA rods with specific combinations of strength and ductility.

Options for Type of Finish

Elmet Technologies offers tungsten heavy alloy in two finish options to meet various customer requirements:

- (1) Rough as sintered (the way the material comes out of our sintering furnaces)

- (2) Turned, ground, or machined to tighter tolerances

Rough As Sintered Finish Tolerances typically in the +/- 3/16” range | |

| Turned or Ground Finish Tolerances typically in the +/- .030” range |  |

For more information about Tungsten Heavy Alloy, please contact us at [email protected] – we look forward to hearing from you!