WHA for Aerospace & Defense Applications

Elmet Technologies is proud to support the military, aerospace & defense industries’ mission-critical applications by providing Tungsten Heavy Alloy (WHA) products of unmatched quality and reliability. Elmet’s strict quality control procedures ensure all products meet the most stringent specifications. Military and defense contractors rely on Elmet’s expertise in manufacturing products requiring the unique material properties of molybdenum, tungsten and their respective alloys.

View Elmet Technologies WHA Data Sheet

WHA for Aerospace & Defense: Industries

Elmet is unique in being the last fully integrated and US owned and operated WHA material producer which is critical to the Defense and Aerospace market which is comprised of several industries. The industries Elmet serves, specific to military, aerospace & defense applications includes:

- Commercial Aircraft (winged aircraft which might take you and your family on vacation)

- Military Aircraft (any fixed-wing or rotary-wing aircraft operated by a legal or insurrectionary armed service of any type)

- Space (vehicles bound for operation above the Kármán line – approximately 100 kilometers or 62 miles or 330,000 feet above Earth’s average sea level)

- Defense (vehicles, stationary systems, components, and or parts which may exist anywhere and in between deep in our Earth’s oceans to the vast regions of deep space to help support our warfighters)

- Warheads, munitions and fragmentation – fragmentation, KEP, shape charges and nozzles

Within all of these defense and aerospace industries, semiconductors, electronics, and other flight and or mission critical equipment exists. Many defense applications encounter damaging radiation or other intangible flux effects present on this Earth or in space. Elmet’s materials play a key role in shielding sensitive components from such environmental conditions. Additionally, high density masses are often strategically placed to manage mechanical performance across an immense range of operational scenarios. WHAs are employed to enable armor-piercing ammunition and other high kinetic projectiles, while WHAs can also be used as armor on a vehicle.

The Department of Defense requires compliance to DFARS 252.225-7052 – is your tungsten DFARS compliant? .

Learn about the latest rules and regulations regarding tungsten and WHA.

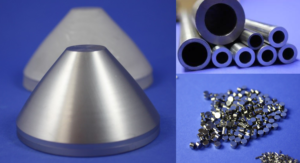

Products for Aerospace & Defense

Common Elmet WHA aerospace & defense products are:

- Munitions

- Fragmentation sleeves

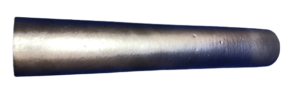

- Kinetic energy penetrators

- Forging dies

- Armor

- Vacuum tube filaments

- High-reliability electronic components

- Near net shape preforms

- Mass dampers

- Balance weights

- Shielding products (for X-rays, but not limited to)

- Wire, sheet, and components for microwave tubes

View Elmet Technologies Aerospace & Defense Products Brochure

Elmet Technologies provides advanced tungsten and WHA solutions to the aerospace industry’s most rigorous requirements by offering a wide array of high-quality components:

- Precision Machined Components

- Ballasts

- Performance Skins

Tungsten Heavy Alloy Capabilities

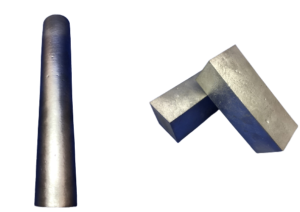

Elmet Technologies presses and sinters high-quality tungsten heavy alloy (WHA) blocks, rods, and shaped parts. Sintered WHA blanks can be further rolled or swaged by Elmet to produce plates, sheets, and rods with ultimate tensile strengths exceeding 180 ksi (1240 MPa) and elongations exceeding 5%. Elmet also precision machines WHA parts for use as ballast weights, radiation shields, boring bars, ordnance components, and other components that require high density and good ductility.

As a 100% US based supplier, Elmet produces its own pure tungsten powder at its facility in Lewiston, Maine and has large blending and alloying capabilities.

Elmet Technologies: Your Edge in Performance Metals

We take great pride in being the last and only fully integrated US-based producer of both molybdenum and tungsten flat and round mill products. We are a committed and leading partner to the defense and aerospace industries and others seeking a world-class refractory metals partner. Both our fabricated and mill products are available in a variety of sizes and form factors. Additionally, we have extensive machining capabilities that allow us to meet even the most challenging needs of our customers.

Elmet’s facilities are AS9100 & ISO9001 Certified, and ITAR Registered with DLA 2345 Approval.

To learn more about our WHA capabilities for aerospace & defense, please contact our experts at [email protected]